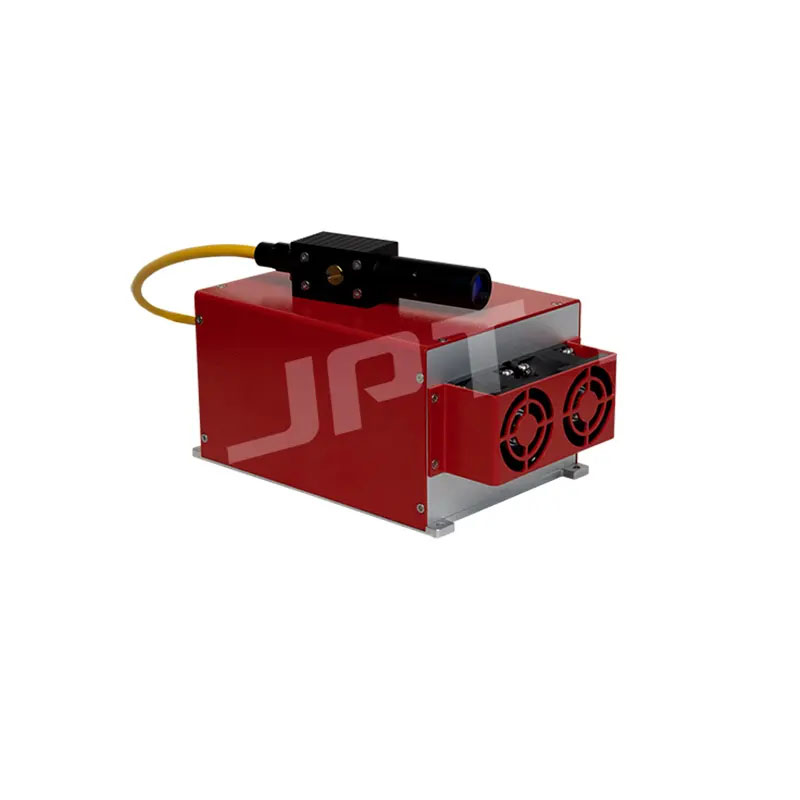

The JPT M7 series 20W and 30W fiber lasers are core light sources for Laser Marking Machines, embodying "MOPA-level precision" in their DNA. Using a directly modulated semiconductor laser as the seed beam, it completely breaks free from the "fixed pulse width" constraints of traditional Q-switches, allowing independent adjustment of pulse frequency and pulse width—essentially equipping each

Marking Machine with a "variable frequency brain." Whether replacing a

Dot Peen Marking Machine to mark 0.2 mm deep QR codes on aluminum shells, or replacing a

Pneumatic marking machine to perform micro-crack-free cutting on thin stainless steel plates, the M7 can continuously output high peak power, providing "cold processing" level precision and consistency for high-speed production lines, cleanrooms, or aerospace applications.

Applications

- Thin Plate Cutting/Welding: With a beam quality M2 < 1.3, the laser cuts through 0.1 mm copper foil like a "light knife," with a smaller heat-affected zone than the mechanical shock of a

Dot Peen Marking Machine.

?

- Laser Engraving and Micro-Drilling: Engraving 6 μm micro-holes on zirconia surgical blades with flawless edges easily surpasses the physical limits of traditional pneumatic marking machines.

?

- Laser Rust Removal and Surface Cleaning: Non-contact, sandpaper-free, and chemical-free, a cleaning speed of 10 cm2/s transforms old molds into "new parts," leaving a perfect base for subsequent laser marking.

?

- Anodizing/Coating Removal: Precisely removes the 8 μm anodized layer from the mid-frame of mobile phones without burning the base material, increasing yield by 15% compared to mechanical cutting.

?

- On-the-Go Marking: With encoders and vision positioning, real-time coding is achieved on a 52 m/min production line, replacing the "stop-mark-go" cycle of traditional marking machines, directly doubling production capacity.

?

Optional Model:

?

M7-20 W: Tailor-made for general high-precision

Laser Marking Machine scenarios, easily marking 1.5 mm high-reflectivity silver characters on plastic shells, replacing low-power dot-peen marking machines. M7-30 W: A significant power leap, capable of engraving 0.3 mm deep serial numbers on 304 stainless steel in 5 seconds, achieving efficiency comparable to a 50 W Q switch while maintaining the fine grayscale of MOPA, allowing even high-end Pneumatic marking machine users to seamlessly upgrade to laser solutions.

?

Typical Industry Cases:

?

Electronics/Semiconductors: 0.3 × 0.3 mm DataMatrix on IC trays with a 99.9% read rate, completely eliminating the "micro-crack" risk associated with Dot Peen Marking Machines.

?

Automotive Parts: ABS sensors laser-welded and then marked in flight using the same M7, each item with a unique code, traceable for 15 years.

?

Medical Devices: Removing oxide layers and performing UDI laser marking on titanium alloy implants in one step, meeting FDA unique identification requirements.

?

Aerospace: Removing 12 μm anodic film and engraving batch numbers on 7075 aluminum wing ribs without compromising fatigue strength, a task traditional Pneumatic marking machines cannot handle. Jewelry/Tools: 0.1 mm micro-letters on the inner curve of a gold ring, achieving a grayscale photo-quality effect, making "laser signature" a new selling point for brand premium.

?

Why choose the JPT M7 series?

?

It gives every Laser Marking Machine the freedom of "pulse programming": a narrow pulse width of 2 ns can achieve "cold marking" for Dot Peen Marking Machines, while a wide pulse width of 500 ns can achieve "deep white marking" for Pneumatic marking machines. Higher single-pulse energy and a flat-top spot size mean fewer passes, lower heat input, and faster cycle time—helping manufacturers increase production efficiency by 30% while pushing processing quality to a new "zero-defect" benchmark. Choosing the M7 means choosing a future-oriented "all-around laser engine" compatible with all Marking Machine applications.