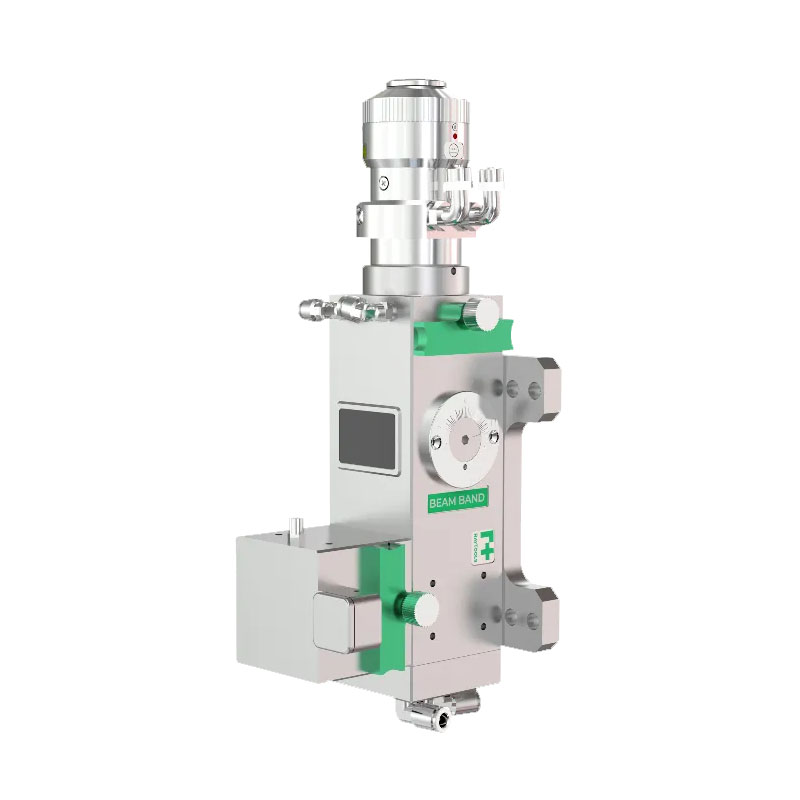

The AK04F is not a traditional

Marking Machine, but an integrated laser edge-sealing head that instantly transforms a 4 kW fiber or semiconductor laser into a "high-speed edge-sealing

Laser Marking Machine." It reverses the flat-top optical path technology originally used for laser marking and applies it to the sealing process: a circular Gaussian beam is folded into a 20 mm rectangular flat-top spot by a purely optical system, with energy uniformity of ±3%, much like applying a layer of "laser tape" to the board, yet it produces a smoother finish than the mechanical indentation of any

Dot Peen Marking Machine, and is faster and quieter than the impact-based sealing of a

Pneumatic marking machine. The

Lens is directly water-cooled, weighing only 3 kg. Similar to changing the field lens on a marking machine, different focal length lens groups can be rotated and changed within 5 seconds, achieving stepless spot coverage from 10 × 2 mm to 40 × 5 mm, and full-band coating of 900–1100 nm. This allows the same machine to be used for furniture edge banding in the morning, car roof cutting in the afternoon, and then returning to Laser Marking Machine mode to add traceability codes to parts in the evening.

Product Advantages

?

1. Fixed rectangular spot edge banding head: Designed specifically for high-volume single-item production lines, it can run continuously for 24 hours after a single setup, offering significantly higher processing stability than

Dot Peen Marking Machines that require frequent needle changes.

?

2. Compact structure: Overall dimensions are 120 × 95 × 85 mm, 40% smaller than the sealing module of a Pneumatic marking machine of the same power. It can be directly mounted on the sixth axis of an existing robot without additional balancing weights. 3. Rectangular flat-top energy distribution: Consistent melting depth of the edge sealant layer, eliminating "smile curve" defects, increasing yield from 92% with traditional Gaussian spots to 99.5%.

?

4. Wide lens compatibility: Large aperture of 38 mm, broadband coating of 900–1100 nm, compatible with IPG, nLight, Trumpf, and

Other fiber lasers, and also supports 976 nm semiconductor lasers, providing upgrade space for factories to achieve "one machine, multiple functions"—the same host can be used as a Laser Marking Machine for QR code printing in the morning, and then transformed into a dedicated edge banding line by switching to the AK04F in the afternoon.

?

Applications

?

- Furniture and cabinet panels: Completes 1 m of ABS/PVC edge banding tape in 0.4 seconds, 3 times faster than hot melt adhesive edge banding, with no glue lines or volatiles, directly replacing the pressing station of a Pneumatic marking machine.

?

- Automotive Parts: Edge sealing of aluminum alloy battery trays, 0.2 mm weld depth, IP67 sealing rating, replacing the traditional double-coating process of Dot Peen Marking Machines, reducing costs by 18 RMB per vehicle.

?

- Packaging and Protection: Pharmaceutical cold aluminum blister sealing, rectangular laser spot fusion of a 20 mm wide area in one go, sealing strength ≥ 70 N/15 mm, meeting FDA sterility requirements. It can also complete batch number marking on the same Laser Marking Machine, achieving one-stop "edge sealing + marking".

?

The AK04F fixed rectangular laser spot edge sealing head combines the precision of a Marking Machine, the speed of a Laser Marking Machine, the permanence of a Dot Peen Marking Machine, and the reliability of a Pneumatic Marking Machine, all within a compact 3 kg body. Whether you are running a large-scale furniture production line or a flexible automobile production line with multiple varieties and small batches, you only need an Allen wrench to switch from "laser marking" to "laser edge banding" in 30 seconds. This allows the same laser to mark traceability codes during the day and seal parts at night, shortening the return on investment cycle by 40%.