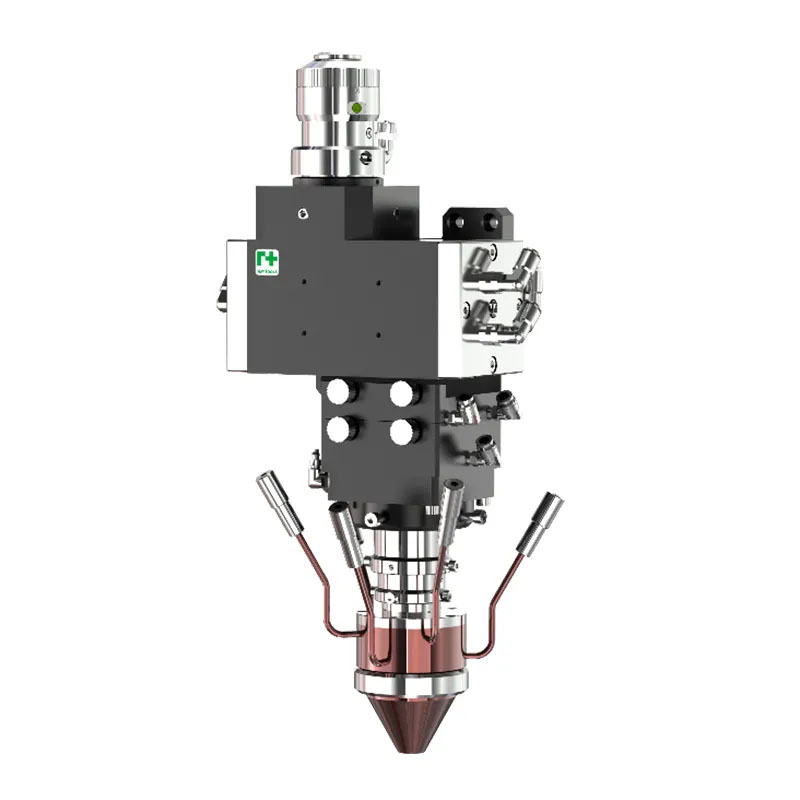

The AL06K (6 kW) and AL20K (20 kW) are not traditional marking machines, but rather a high-power copper reflective cladding head that brings "

Laser Marking Machine-level" micron-level energy control to the cladding process. Circular or square beams can be switched with a single button, much like changing the needle type on a

Dot Peen Marking Machine: the circular beam is used for high-speed cladding, and the square beam for wide-area overlap. Both can continuously output 6 kW or 20 kW peak power under the constant temperature protection of a water-cooled copper mirror. The processing speed is 4 times faster than the powder feeding and re-impact solution of a coaxial

Pneumatic marking machine, without any mechanical wear or noise.

- Copper Reflection + Direct Water Cooling:

Lens temperature difference <3 ℃, continuous 24-hour power decay <1%, allowing even large gears to enjoy the same "cold" processing stability as a Laser

Marking Machine.

?

- Online switching between circular and square beams: As simple as changing the tungsten carbide needles on a

Dot Peen Marking Machine, the beam shape switching is completed in 10 seconds. A circular beam (Φ1–4 mm) is used for precision repair, while a square beam (4 × 4 mm) is used for high-speed cladding. The process window is 5 times wider than the single-point impact of a traditional Pneumatic marking machine.

?

- Dual power platforms: 6 kW & 20 kW: The AL06K can replace the welding station of 8 simultaneous Pneumatic marking machines; the AL20K can complete a 0.5 mm cladding layer in 0.1 seconds, providing a wear-resistant coating that is metallurgically bonded to the base material for aircraft landing gear, eliminating the need for secondary positioning and marking by a workshop marking machine.

?

- Full Material Compatibility: Suitable for materials ranging from aluminum alloys and titanium alloys to high-carbon steel, achieving a 3–5 HRC increase in hardness and a cladding layer porosity of <0.5%. It can directly replace the cold-working strengthening of Dot Peen Marking Machines while retaining the surface finish of Laser Marking Machines.

- Aerospace: A 0.3 mm corrosion-resistant layer is clad onto the 7075 aluminum wing arm. Subsequently, a low-power Laser Marking Machine galvanometer is installed at the same robotic arm end, enabling in-flight DataMatrix marking. This achieves "cladding + marking" in a single machine, saving 40% of cycle time.

?

- Automotive Manufacturing: Fe-B alloy is clad onto the inner wall of GTL diesel engine cylinder liners, extending wear life by 3 times. Immediately after cladding, coaxial CCD positioning is used, and 20W marking mode is initiated at the same station, replacing the "secondary handling turntable" of traditional Dot Peen Marking Machines and eliminating secondary clamping errors. - General Manufacturing: High-speed cladding at 20 kW is used to clad the partially spalled areas of a large 42CrMo gear shaft, achieving a single-pass weld width of 12 mm and a weld depth of 1.8 mm, with a machining allowance of only 0.2 mm. The repaired hardness is 55 HRC, with a difference of less than 1 HRC compared to induction hardening, completely eliminating the lengthy "welding-grinding-flaw detection" process of traditional Pneumatic marking machines.

?

Overview: The AL06K/AL20K combines the precision of a Laser Marking Machine, the graphic freedom of a Marking Machine, the localized strengthening depth of a Dot Peen Marking Machine, and the large-area efficiency of a Pneumatic marking machine into a compact body weighing only 2.8 kg (AL06K) or 4.5 kg (AL20K). Whether you are repairing the leading edge of a 5 mm aerospace blade or cladding a 2 m marine crankshaft, you can simply call up the "high-speed cladding - precision repair - laser marking" three-process package on the touch screen. The spot shape and power can be switched in 2 minutes, allowing the same laser to first clad and then mark. Using a high-power cladding head, the surface strengthening workshop and traceability station are combined into a zero-springback, all-laser "cladding + marking" composite production line.